The Advantages of Using litho printing for Business Collateral

The Advantages of Using litho printing for Business Collateral

Blog Article

A Comprehensive Guide to Recognizing Litho Printing Methods

The globe of litho printing, a technique stemming from the late 18th century, is a remarkable mix of background, advancement, scientific research and art. This detailed overview will untangle the intricacies of this printing method, from the composition of litho inks to the difficulties faced in modern-day applications. As we venture right into the ins and outs of lithography, the relevance of automation and sustainability in ensuring its future importance becomes increasingly clear. Stick with us as we trip right into the exciting world of litho printing.

The Historical Evolution of Litho Printing

The historic trajectory of litho printing, an essential innovation in the realm of interaction, is a captivating tale of human resourcefulness. Birthed in the late 18th century by Alois Senefelder, this method was at first an affordable approach of publishing staged works. Lithography, stemmed from the Greek words for 'stone' and 'to compose', used a smooth stone surface to move pictures onto paper. The process advanced with the arrival of the rotary press, which substantially enhanced efficiency (litho printing). In the 20th century, the development of offset lithography transformed the industry, enabling mass manufacturing of top notch prints. Each phase of litho printing's advancement showcases mankind's ruthless search of performance and high quality in visual communication.

Decoding the Science Behind Litho Printing Inks

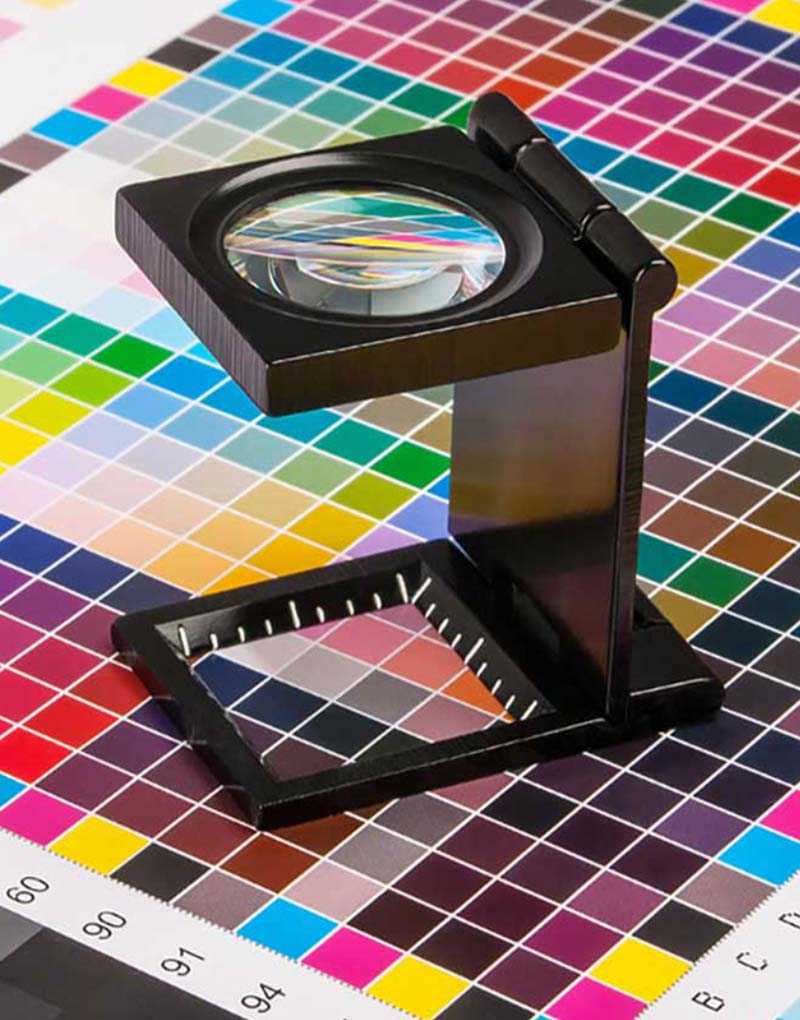

Moving on in the expedition of litho printing methods, the emphasis currently shifts to the science behind litho printing inks. The make-up of these inks, their drying process, and shade mixing methods form the backbone of this intricate art kind. Recognizing these components is essential to grasping the craft and achieving the preferred print outcomes.

Composition of Litho Inks

In lithographic printing, the essential function of litho inks can not be overemphasized. Pigments, the color-providing components, are finely ground bits put on hold in the lorry, a fluid that lugs the pigment onto the printing surface. Each element plays an essential component in the last print's top quality, making the exact solution of litho inks an intricate scientific research.

Ink Drying Process

From the structure of litho inks, focus transforms to the fascinating process of ink drying out. The drying out procedure is important, as it impacts the final print's quality and longevity. 2 main approaches are utilized in litho printing: oxidative drying and absorption. Oxidative drying out entails the ink responding with oxygen airborne to create a difficult, dry movie. This approach gives a durable finish, yet can be slower contrasted to absorption. Absorption, on the various other hand, includes the ink seeping right into the paper fibers, which is a faster procedure but can lead to much less vibrant colors. The choice in between these approaches is dependent upon factors such as print speed needs, the paper kind used, and the wanted surface.

Color Mixing Techniques

While the drying procedure plays a vital role in litho printing, the science of shade mixing strategies holds equal importance. The scientific research behind litho printing inks additionally takes into account find more info the transparency of the ink, which influences how colors overlay and mix.

The Art and Style Components in Litho Printing

Litho printing breathes life into art and layout via its distinct aspects. The procedure entails creating a picture on a lithographic sedimentary rock plate or steel plate with a smooth surface area. The image is then published onto a tool, generally paper, by transferring the ink from home plate. What sets litho printing apart is its capability to duplicate complex layouts with high integrity, making the result almost identical to the original artwork. This is achieved with using various line strategies such as hatching, stippling, and cross-hatching, which permit a series of tonal results. Litho printing suits a range of shades, allowing artists to create dynamic and vivid prints. This mix of accuracy and flexibility makes litho printing a favored option for lots of musicians and designers.

Modern Applications of Litho Printing Strategies

Litho printing methods have discovered extensive usage in the contemporary commercial sector. Its impact and significance proceed to grow with the arrival of brand-new advancements and technologies in the field. This section will certainly explore these contemporary applications and the transformative function they play in the printing industry.

Industrial Litho Printing Utilizes

Litho printing stays a critical component of the industrial sector. High-volume printing tasks, such as the production of books, papers, and product packaging, count on litho printing for its ability to supply premium picture top quality and price effectiveness. Litho printing also provides a broad shade range, remarkable to that of electronic printing.

Innovations in Litho Printing

Pressing the borders of conventional techniques, modern-day advancements have actually fueled a host of advancements in litho printing. One prominent advancement is electronic litho printing, which my explanation combines the virtues of electronic technology with litho's top quality output. These advancements underscore the enduring significance of litho printing in the modern world.

Discovering the Process of Litho Printing: Detailed

Obstacles and Solutions in Contemporary Litho Printing

Despite the precision and custom that litho printing happily upholds, it is not without its collection of modern obstacles. Digital litho printing enables for economical short runs and easy personalization, dealing with the concern of variable information. Thus, while there are difficulties, the litho printing sector is proactively adapting to fulfill them head-on, ensuring its relevance in the future.

Conclusion

In verdict, litho printing, with its abundant background and scientific intricacies, holds a substantial location in the print sector. The future of litho printing hinges on its capability to adapt to these altering needs, attesting its enduring value in a developing market.

Report this page